|

«Yesterday was a very good event!!!! Thanks for all the effort in organizing it!” – something must have been right, when you receive such an email after an event. It was a trial. For the first time, the companies Inolytix and Novitom together with SLS Techno Trans AG, the technology transfer of the Swiss Light Source, organized an event at the Paul Scherrer Institute (PSI). Around 25 people found their way to Villigen and discovered the fascinating possibilities in 3D imaging for industry.

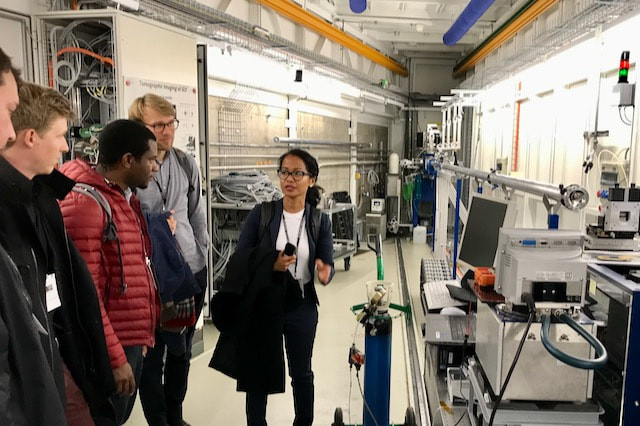

Stefan Müller, SLS Techno Trans AG, introduced the whole PSI with some facts and figures, namely mentioning the 2100 employees and the 1’400 publications annually. But not only this. For SMEs, there is a special funding available called CALIPSOplus, which provides some (but not all…) services free of charge – a great possibility to try some new analytical tools! For more information see the link at WayforLight.eu. The collaboration of Inolytix, Novitom and SLS Techno Trans AG is supporting many of the unknown steps towards an effective and most easy access of companies. This includes efficient project management and reports, which can be used for the management too, as Ralf Dümpelmann, CEO and founder of Inolytix, explained. Many practical examples from different industries as cosmetics, food and composite materials were provided by Barbara Fayard, CEO and cofounder of Novitom. One example was the change of the microstructure of a composite material over time in-situ at 300°C. It becomes clearly visible how the polymer matrix penetrates into the fibres and reduces the porosity to an acceptable level. Margie Olbinado, a scientist at PSI, explained the differences of microtomography and the nanotomography, as well as ptychographic X-ray nanotomography. The microtomography is very fast within seconds or minutes and objects of a few mm can be measured with resolutions up to 10 micrometers or 1 micrometer, respectively. While the ptychographic nanotomography achieves resolutions down 15 nm but requires beam times of several hours and very small samples. Additive Manufacturing, or more easy 3D-Printing, is not easy to optimize in terms of speed. Christian von Burg, CEO and founder of Sintratec AG, an innovative producer of 3D Printers for polymeric structures in Brugg, illustrated, how the microtomography and the 3D imaging helped them to optimize their operating conditions. How accurately can be measured? This question was answered by Benjamin Bircher in high talk “Industrial high-resolution CT for metrology”. It was fascinating to learn, that Metas, the Swiss institute for metrology, provides a very solid basis to produce and to measure accurately – definitely a Swiss speciality! The experimental setups of micro- and nanotomography were in detail explained by the PSI researchers during a fascinating tour through the large hall of the Swiss Light Source, the only synchrotron facility in Switzerland. Do you have 3 dimensional objects – and the need to optimize and understand the inner structure? Contact us! We want to make you more successful.

1 Comment

|

|

We are eager to support you.

|

RSS Feed

RSS Feed