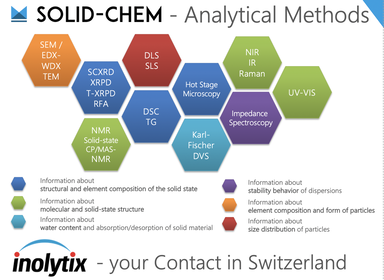

Inolytix represents now SOLID-CHEM in Switzerland Are you fully aware that many essential physicochemical properties of an Active Pharmaceutical Ingredient (API) depend on its solid-state structure? Solubility, bioavailability at desired levels, shelf-life stability, hygroscopicity, compressibility, tableting ability, electrostatic charging, plus many others, can be crucial properties. And the decision is not trivial, which kind of solid-state form should be produced or selected for an API and which data are required by patent lawyers. Sophisticated analytical tools and the right expertise are essential for successful evaluations. Inolytix AG represents now SOLID-CHEM GmbH in Switzerland By working together on analytical projects, it became clear that SOLID-CHEM GmbH, Bochum, Germany possesses special equipment of instruments and the right expertise – especially for the pharmaceutical industry but also for others. Customers reacted very positively, for example, “…now my favorite CRO for ssNMR….”. Therefore, we are pleased to announce that Inolytix AG is now an exclusive partner in Switzerland for services offered by SOLID-CHEM GmbH. Offering a comprehensive service of solid-state analysis Exploring suitable solid-state forms (amorphous, polymorphs, salts, co-crystals, or solvates) requires a diverse methodological portfolio plus the expertise and the compounds for (co ) crystallization. Moreover, you need to precisely define all the appropriate analytical tools when matching your API with the final formulation. Many methods exist for determining solid-state forms because the intermolecular interactions responsible for the solid-state have a very subtle character. Diffraction- and thermochemical methods, particle determination, ssNMR, humidity determination, etc. - all this requires collaborating specialists overviewing such cross-networking analyses. Finally, they have to understand the different languages when speaking to organic, bio, theoretical, and technical chemists, to pharmacists, formulation specialists, and, last but not least, with patent lawyers. It will be our pleasure and ambitious task to provide you with the best analytical services for solid solutions for the solid-state of pharmaceutical products ranging from • pure APIs to complement tablet formulations • screening procedures of solid forms, • data for patents or stability tests Any questions about your solid product form? Contact us, and let’s discuss it! Please find below two supporting documents:

Inolytix, Aargau (Switzerland) - Inolytix is a startup launched in 2014 with the focus on accelerating product development and true understanding for the chemical and pharmaceutical industry. Through new and innovative analytical methods delivered by reliable and experienced partners such as SOLID-CHEM, Inolytix offers a customer-friendly service for R&D departments: providing the customer with a clear expert view and access to effective, but less known analytical methods, Inolytix manages the whole process from quotation to the industry- oriented report on the results.

Contact: Dr. Ralf Dümpelmann (for Switzerland), Founder and Managing Director [email protected], phone: +41 79 312 9327, www.inolytix.com SOLID-CHEM GmbH (Germany, Bochum) - Founded by Prof. Boese and Dr. Schauerte as a spin-off from the University of Essen, SOLID-CHEM GmbH has become an expert center of solid solutions for the solid-state of pharmaceutical products. The philosophy is, to support customers with expert opinions based on experimental, scientific, carefully retrieved data and on precisely documented experiments. Results and reports from investigations can be potentially used for litigations, and therefore, scientific integrity is our absolute priority. Contact: Dr. Carsten Schauerte, Managing Director and Co-founder, [email protected], phone: +49 234 936 90610, www.solid-chem.de

1 Comment

Ever wondered how your material looks inside? New analytical methods like Microtomography (XMT) are able to generate image data we did not have before: huge amounts of data. In our case 2048 images per sample. Based on synchrotron based X-ray radiation and the computing power of today the sample is analysed in a few minutes or even seconds - with voxel sizes down to 325 nm and quantifiable image analysis. Academic high-tech? Not at all! Industry is encouraged to use the facilities and Inolytix helps you to interact smoothly with researchers. Discover your own products, see what normally stays hidden! The Case Study of heterogeneous catalyst pellets Combination of Methods: 3D-characterization + Microtomography Conventional analysis: Scanning electron microscopy of one (1) image after sample preparation. The Inolytix way: Synchrotron-based X-ray Microtomography with 2048 image slices in 4 minutes without any sample preparation. 3D-image analysis for structural quantification. Are catalyst pellets homogenous? Do the pelletising process and any treatments deliver uniform morphologies? Are there heterogenities or irregularities? These were the underlying questions of a recent study of catalyst pellets we performed. Without any sample preparation, the 3D-characterization of catalysts pellets was possible with synchrotron based X-ray microtomography. Thanks to the additional quantitative image analysis of thousands of images, we could reveal that the catalyst pellets examined had heterogeneous inner structures with distinct differences. Surprisingly, the structural differences were clearly visibly at a scale above 300 nm, i.e. well beyond the scale of micro- and mesopores. Hidden aspects became visible - with new insights for our customer! Find the appropriate analytics for your case Inolytix is your expert to pick and choose the methods that make the most sense for your needs. We draw upon our +20 years of R&D experience to add a 360 degree interpretation of your results. Your Partner for the entire cycle from experiment design to measurement to analysis and interpretation. Contact us for a free consultation call for your specific request. Video about optimizing your IGC measurements by Prof. Steven AbbottAfter the series about IGC Steven Abbott added another video in which he explains how you can optimize your IGC measurements. You also find the text on his website  Use IGC to discover hair treatment and damages Inverse Gas Chromatography (IGC) was the analytical tool of choice for surface characterizations of hair (and hair treatment), pigments (compatibility) and silica (for tyres). These were some of the interesting insights of the IGC Symposium, April 10th in Frankfurt organized by Adscientis and Inolytix, http://inverse-chromatography.com/. Dr. von Vacano, BASF, showcased physical characterization studies of native, bleached and treated hair using AFM, XPS, ZP (surface charge) and IGC. The dispersive surface energy measured by IGC is the best indicator for surface damage with low statistical errors and the best quantification. Even the promotion of a new product uses the evidence by IGC. The combination of all methods provided a thorough understanding of hair damages and conditioning. Measurements of pigment surfaces Dr. Gebhardt, DSM Coating Resins, presented measurements of pigment surfaces by IGC and some surprising findings in term of acid/base character, nano-roughness and specific chemical interactions. The question behind this study was the compatibility to the resin matrix, the coating formulation and treatment of the pigments. The results, like basic properties and high affinities to nitrile, amide and carbamate groups, can be used to optimise pigment-coating systems. Pigment suppliers were encouraged to share information about surface treatment and potentially collaborate. The next generation of energy saving tyres Dr. L. Guy, Solvay, explained the challenges to develop next generation of energy saving tyres and the interactions between silica surface, carbon black and the polymer nature. The use of IGC is key to understand these interactions. Useful are the different techniques as IGC-ID (infinite dilution) to measure dispersive surface energy and IGC-FC (finite concentration) to measure the surface heterogeneity and e.g. BET with alkenes instead of N2. Highly qualified experts delivering additional applications Additional background information and further applications of IGC was provided by professors of different universities. The introduction was presented by Dr. H. Balard, who started using IGC in the year 1978 and published 52 articles on IGC. Altogether, this was an inspiring symposium with highly qualified experts. There is no fancy new equipment behind IGC (which may explain the lack of broader interest…), but simply a really valuable methodology and expertise. Personally, I am certain that more and more R&D departments will take advantage of it – sooner or later.  That was my initial reaction when I first heard about iGC. I learned then, that the trick about „inverse“ is that particles and fibres of unknown surface characteristic are filled INSIDE the column of a GC and probes of well-defined gases are pulsed over them. The interaction of different gases with the surface provide the retention times and tailing – and thereby quantitative values for dispersive surface energy, polar contributions, acid/base properties at surface level or a „nanoroughness“ by comparing linear and branched alkanes – amazing! OK, another method, but where can I use it and why? Surfaces determine the quality of many products, the compatibility of silica in rubber, pigments in plastic or even (or especially) the feeling of hair. Most often the application is measured, but the real understanding of what changed at surface level is lacking. This is innovation by chance and product optimization by trial and error. And beside product invention or optimization there are often other obscure problems: batch-to-batch variations, dispersion behaviour or unexpected changes by milling. What happened to my product? Is iGC complicated? YES and NO. No, because the equipment is basically a GC - not more required. YES, because the preparation, experimentation and interpretation requires experience and a real understanding of the underlying theory. Especially with iGC the saying is true that real value is in the expert and not in the instrument. By chance I found Eric Brendle from Adscientis who explored iGC during his PhD more than ten years ago. Since then he has explored many different surfaces with passion and skills. Not surprising, we are collaborating! Sure, iGC can not answer all questions, ... ... but it is truely an interesting method to characterize surfaces at molecular level. On April, 10th, 2014 a mini-Symposium in Frankfurt with speakers from BASF, DSM, Solvay and several professors will shed more light on a few applications. A good chance to talk to practitioners and academics. There is still the chance to register -> http://inverse-chromatography.com Surfaces are truely remarkable. Only a few layers of molecules in the range of nm determine the success – or the failure – of everyday products. Interesting how difficult it is to measure – and how little we know in many cases. |

|||||||||

|

We are eager to support you.

|

RSS Feed

RSS Feed