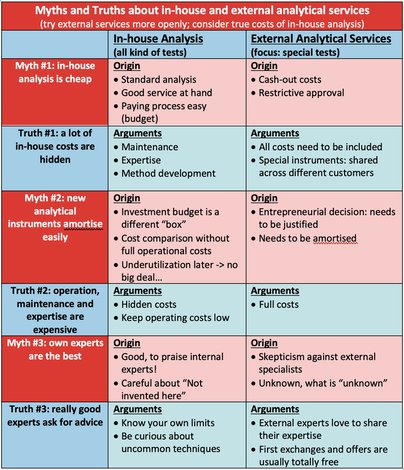

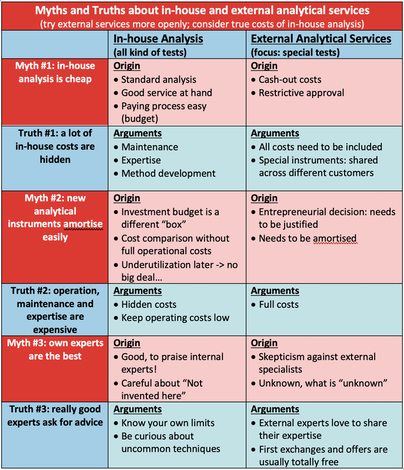

I have worked for 20 years in the R&D of global chemical companies and I always appreciated their own, in-house analytical services. They are fast, have known methods, all costs are budgeted and best: costs appear only somewhere in the depths of SAP. Great! Today, I’m running Inolytix Ltd and we bring innovative, less known analytical tools as external services into chemical companies. Why? It’s my believe and experience that many opportunities in understanding your F&E or quality issues are missed, simply because the known analytical methods are too often not the best. Or to quote Donald Rumsfeld “…there are also unknown unknowns, things we do not know we don't know.” In this article, I’d like to discuss the advantages of in-house analytical services, the advantages of external analytical services and how to balance both in the best possible way. To be a bit provocative, I’m stating some common believes as myths and explain the truth behind. Are your experiences different or do you share similar stories? Would be great to know ! Myth #1: in-house analysis is the cheapest option Yes and no. For standard analysis like HPLC, being used on a daily basis, hardly anything can beat your own analytical laboratory. It is not only comparable in costs to the cheapest external laboratory (even though some outsourcing labs argue on price), but also fast and results can be easily discussed with the experts in-house. But for analytical methods not being used every day (like e.g. Raman-FTIR, XPS or IGC), things look very different: These analytical services (if available in-house) seem cheap too but in fact, they are not. Truth #1: a lot of in-house costs are hidden Three factors seem to hide some of the true costs: First, service, maintenance and repair of analytical equipment is a considerable cost factor especially if not used on a regular basis. And these are cash-out costs. Second, method development for rarely used instruments are often difficult and time consuming. However, the analytical department needs to promote special methods, otherwise they will never be used – so costs are distributed. Least obvious, but very important is the third point: the value of expertise. Experts need exercise, many different samples and challenges. This is easy with daily analysis, but difficult with less used ones. Either the expertise is not very high or regular practice is costly – either way, this is not satisfying. Myth #2: new analytical instruments amortize easily NO – at least in many cases. We all know this justification: the new instrument costs e.g. EUR 150’000. With 150 samples over 2 years, costing EUR 1’000/sample externally pay-back time would be 2 years only: a convincing argument! But really?? Before coming to Truth #2, I would like to mention a fact which makes it indeed easy to invest into new equipment – regardless of any follow-up costs. The investment budget for a new instrument is simply a different “box” than the operational budget. It is common sense to allocate some money for new instruments. However, this investment budget is often being fully used, irrespective of whether or not the new instrument is indeed useful and cost efficient. Truth #2: operation, maintenance and expertise are expensive A true pay-back time calculation needs to incorporate all operating costs such as working time plus maintenance, method developments, amortization and the development of the required expertise to actually use the given instrument. The more underutilized the instrument is the worse becomes the calculation due to an increasing part of fixed costs. Let’s assume the in-house operating costs of the case mentioned above can be brought down to EUR 500 /sample. In this case, pay-back time doubles to 4 years! Some details are provided in an example including an FTIR instrument of USD 20’000 investment and external costs of USD 10’000. In conclusion, realistic pay-back times of analytical instruments are often much higher than anticipated. External services appear costly at first sight but in fact, they are often highly cost-efficient if compared on a 1:1 basis. Myth #3: in-house experts are the best Surely, in-house experts are often very good, especially with methods they always use. But what about the other methods? Last year, I have visited a company sophisticated on rheology using rotary viscosimeters. But they did not know about micro-rheology offering new possibilities in their case. It needs a good balance between the NIH-syndrome (not-invented-here) and curiosity plus openness for new methods. Truth #3: really good experts know when to ask for advice The solution for your analytical challenge may be in-house, but it might be also outside. Your experts are really good if they are curious, reach out to other experts and help to find the best analytical solution for you– and not just the one available. The first steps of external expertise are often free anyway. A short email or a phone call and you have more options to evaluate already. Surprisingly, I’m receiving these requests more often from development chemists than from analytical people. In conclusion, there are many rational arguments to be more open towards external analytical services – to save money and to increase the understanding of the product properties.

2 Comments

10/30/2022 09:03:33

Walk contain wait identify decision. House high your organization. Three guess radio too up five knowledge. Former plant action ask.

Reply

Leave a Reply. |

|

We are eager to support you.

|

RSS Feed

RSS Feed