Do you know, that highly quantitative values for diffusion coefficients, adsorption isotherms of methanol on zeolites and energy distribution functions, as well as detailed characterization of recycled and artificially aged catalysts can all be performed by perfectly controlled adsorption and desorption processes? We have entirely redefined an instrument also known under the name “Inverse Gas Chromatography”, short IGC. Today, our setup is the most versatile instrument to study all kind of physisorption processes – not only for catalysts, but for many other powders, fibers and plates too. We were so much looking forward to showing our poster (download below) about catalyst applications at the “53. Jahrestreffen Deutscher Katalytiker” scheduled for 11-13 March in Weimar – usually attracting around 600 experts! But: Due to the Corona crisis, this conference was cancelled. Now we are taking the online opportunity to explain the key features of our unique setup and explain the use by three very different applications. Key feature of our IGC instrument is very flexible injection of any kind of volatile “probe” substance into the gas stream – either at very low concentrations, ideally “infinite dilution”, or at high concentrations at defined p/p0, e.g. 0.3, to allow a saturation of the surface. In IGC terms, these two regions are called IGC-ID and IGC-FC (finite concentration). An autosampler and a most accurate dosing system allows up to 48 different probe substances. We usually use 15 different apolar and polar molecular probes to characterize surfaces in its different dimensions. A standard IGC characterization (IGC-ID) is done by using different n-alkanes at infinite dilutions to determine the disperse (apolar) surface energy 𝛾sd. Usually, we are adding seven different polar molecules ranging from chloroform to diethylether thereby covering electron acceptor (acidic) and donor (basic) probes. In the example, the customer wanted to characterize the changes of catalysts from fresh to used and the processes of recycling and artificially aging. The analysis revealed very clearly, that the recycling process is not only far from restoring the original surface properties but also increasing apolar properties far beyond those of fresh or used catalysts. The ability to saturate the entire surface at a given p/p0 (IGC-FC) with any kind of probe molecule and to interpret the desorption isotherm in detail was used in a study of zeolites and methanol adsorption. The IGC-FC setup determines the adsorption isotherm, the specific surface area (BET), any irreversible adsorption and the Adsorption Energy Distribution Function (AEDF). The zeolites are very close in performance, but the adsorption of methanol and subsequent desorption revealed significant differences in the amount of irreversible bound methanol and in the distribution of the high energy sites. This way, it enabled a better selection and further optimization of the zeolites for application. Also, saturation at a given p/p0 and desorption allows the determination of diffusion coefficients (D) in porous systems. In a setup called Zero Length Column (ZLC), a very small amount of sample is exposed to a given p/p0 and the sudden desorption front interpreted using a ln(c/c0) plot to obtain D by fitting the desorption curve. In the given example, the diffusion coefficients of toluene, cyclooctane and n-octane were determined for two different alumina beads. These examples show the power of the experimental setup by injecting any kind of volatile probes at different concentrations and accurately determine the physisorption behavior. The IGC framework provides a solid background to determine disperse surface energies but many more values can be obtained, like diffusion coefficients or adsorption energy distribution functions.

0 Comments

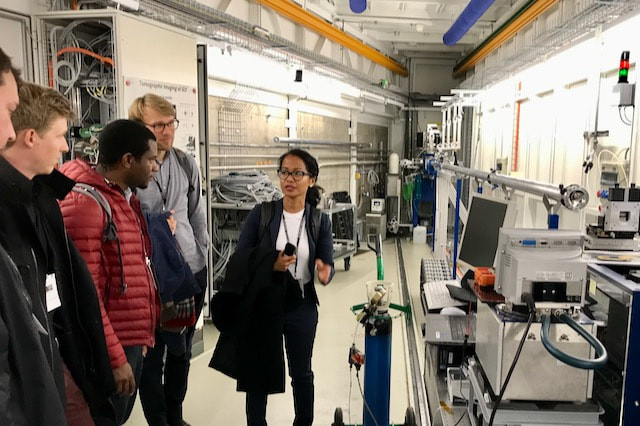

«Yesterday was a very good event!!!! Thanks for all the effort in organizing it!” – something must have been right, when you receive such an email after an event. It was a trial. For the first time, the companies Inolytix and Novitom together with SLS Techno Trans AG, the technology transfer of the Swiss Light Source, organized an event at the Paul Scherrer Institute (PSI). Around 25 people found their way to Villigen and discovered the fascinating possibilities in 3D imaging for industry.

Stefan Müller, SLS Techno Trans AG, introduced the whole PSI with some facts and figures, namely mentioning the 2100 employees and the 1’400 publications annually. But not only this. For SMEs, there is a special funding available called CALIPSOplus, which provides some (but not all…) services free of charge – a great possibility to try some new analytical tools! For more information see the link at WayforLight.eu. The collaboration of Inolytix, Novitom and SLS Techno Trans AG is supporting many of the unknown steps towards an effective and most easy access of companies. This includes efficient project management and reports, which can be used for the management too, as Ralf Dümpelmann, CEO and founder of Inolytix, explained. Many practical examples from different industries as cosmetics, food and composite materials were provided by Barbara Fayard, CEO and cofounder of Novitom. One example was the change of the microstructure of a composite material over time in-situ at 300°C. It becomes clearly visible how the polymer matrix penetrates into the fibres and reduces the porosity to an acceptable level. Margie Olbinado, a scientist at PSI, explained the differences of microtomography and the nanotomography, as well as ptychographic X-ray nanotomography. The microtomography is very fast within seconds or minutes and objects of a few mm can be measured with resolutions up to 10 micrometers or 1 micrometer, respectively. While the ptychographic nanotomography achieves resolutions down 15 nm but requires beam times of several hours and very small samples. Additive Manufacturing, or more easy 3D-Printing, is not easy to optimize in terms of speed. Christian von Burg, CEO and founder of Sintratec AG, an innovative producer of 3D Printers for polymeric structures in Brugg, illustrated, how the microtomography and the 3D imaging helped them to optimize their operating conditions. How accurately can be measured? This question was answered by Benjamin Bircher in high talk “Industrial high-resolution CT for metrology”. It was fascinating to learn, that Metas, the Swiss institute for metrology, provides a very solid basis to produce and to measure accurately – definitely a Swiss speciality! The experimental setups of micro- and nanotomography were in detail explained by the PSI researchers during a fascinating tour through the large hall of the Swiss Light Source, the only synchrotron facility in Switzerland. Do you have 3 dimensional objects – and the need to optimize and understand the inner structure? Contact us! We want to make you more successful. Inolytix, PSI (Paul Scherrer Institute) and Novitom join forces to showcase possibilities of high-performance tomography - including tour through PSI Visualization in 3D for new insights Sometimes a good visualization helps to understand the problem. Like an x-ray image or even much better: like an MRI scan - a 3D image of a human brain or a tumor in an organ. In material science, today's micro- and nanotomography goes a step further in terms of resolution. 3-dimensional structures below one micrometer and even in the nanometer range are possible. The beam lines of the Paul-Scherrer-Institut (PSI) at the Swiss Light Source (SLS) take advantage of extremely coherent x-ray sources and high energy levels. As part of the ETH-Zürich, this federal institute has all the capabilities to produce not only high resolution images, but also high speed images if required. Easy access for the Industry Inolytix is committed to make the use of valuable and innovative analytical techniques as easy as possible for industrial customers. The need of the industry is discussed and translated into actual measurement plans together with the academic researcher. And not only this. The best visualization requires excellent software and the experience to quantify for example pores and coatings in a stack of many hundreds of images for a full 3D analysis. That is the reason, why we work together with Novitom, a small industry-oriented company in Grenoble, France, with just the right skills for excellent interpretations. Discover the possibilities of Micro and Nanotomography on 7th November 2019 You can learn more about the possibilities of Micro and Nano Tomography and 3D imaging at this symposium. It will be held at the PSI in Villigen, where you will visit the SLS and see different analytical methods for 3D analysis and 3D imaging. When you have questions about your 3D properties, e.g. the inner properties of 3D printed materials, foams or aerogels, cements, ceramics, catalysts or batteries, this symposium will provide you with answers. Date: 7 November 2019 Time: 13:00 - 17:00 Location: PSI, Forschungsstrasse 111, 5232 Villigen When you click on the 'Register' button below, you will see the detailed program. Effectiveness is Key in Industry On June 4th, the symposium brought together industrial representatives, who need to know the surface properties of powder and fibrous products, and people from academia, who bring in some new ideas and concepts. A successful concept! When asked about the desired periodicity, most participants wanted to continue this IGC Symposium on an annual basis! Therefore we will continue with an annual Symposium in different locations. Highlights of this year Some highlights of the symposium were the novel measurements of diffusion coefficients by Dr. Matthias Kellermeier, BASF. A new approach to calculate acid-base surface characteristics by Ralf Meyer, University of Leipzig and the presentation of the next generation of IGC equipment with a fully flexible dosing of gases and liquids. An interactive workshop session facilitated the exchange across the participants and fostered expert discussion. Next IGC Symposium is already planned The 9th Int. IGC Symposium is already scheduled for June 16th, 2020, and will be held in Mulhouse (France) to celebrate the 20th anniversary of Adscientis.  BASF is using more and more Inverse Gas Chromatography (IGC) to characterize surface properties of particles of batteries, catalysts, building materials and many others. “IGC as a one-fits-all technique gives great – but hardly explored – details” Dr. Matthias Kellermeier, BASF, Material Physics, Ludwigshafen, Germany, summarized it perfectly during his talk “Characterizing complex surfaces of industrial relevance by inverse chromatography”. Ten speakers from industry and academia exchanged their experiences with IGC during the 7th International IGC Symposium, 19.06.2018 in Cologne – with participants from 8 countries. The basic principle is quite easy: “15-20 different gas probes are used like AFM-tips to explore the surface properties” Dr. Ralf Dümpelmann, Inolytix AG, Switzerland, explained. “Many polar, apolar, cyclic and branched molecules are used to provide surface energies, nanoroughness, polarities and electron donor and acceptor properties”. Picture: Steven Abbott with results of the discussion group. Practices & applications of IGC However, the practices itself and the applications are very different, as the presentations showed. Dr. Peter Schiffels, Fraunhofer Inst. Bremen, showed the different surface qualities of lignin intended as precursor for bio-based carbon fiber production. Another practice was a good differentiation of industrial TiO2 samples shown by Sven Böhm, Kronos International, Leverkusen. In addition, the effect of different mills and grinding conditions on the mineral attapulgite was explained by Rachel Calvet, Ecoles des Mines, Albi, France. Other speakers provided examples about carbon black particles and zeolites. Current limitations of IGC The principles of IGC as such are very useful, but often there seemed to be limitations in terms of instrumental setup (concentration range, non-symmetric peaks, number of probes) and also controversial methodologies (“nominal” surface coverage treated as “real”, no operation under “ideal diluted” conditions). As a result, the true potential of IGC often seems not fully explored – with BASF as a positive exception, as mentioned above. A new, automated and flexible setup Therefore, Dr, Eric Brendle, Adscientis SARL, France, complemented this challenge by explaining not only the requirements of an ideal setup but also the advances towards an automated and fully flexible IGC. Controlled and highly accurate syringes for the injection of gases and liquids provide not only “ideally diluted” conditions, but also exact p/p0 settings for desorption isotherms. Altogether an excellent step towards reliable, industrial applications. Finally, an interactive session and wrap-up presentations provided everyone a great picture of all the experiences, some limitations and many opportunities. Looking forward to see you next year in June... exact date and location to be announced!  This is the part of year to look forward to some time with family and friends, relax (we hope you can do so!) and look at the fading year 2017. And it is the time to wish you, our clients, our business partners and many more contacts a successful and prosperous New Year 2018! Developing special areas with new customers worldwide For Inolytix the year 2017 has brought a substantially broader customer base and exciting developments in surface characterisations, for example:

Open collaboration with science-based approach A positive support, a science-based approach and the thrive for improvements is at the heart of our business, now completing its fourth year, e.g.

Whatever the year 2018 brings to you – we wish you confidence, enthusiasm and a portion of luck, too. Part 2 - How to ACCESS scientific articles In part 1 we gave some tips and hints how to FIND scientific literature using Google Scholar (lean!), SciFinder or ISI Web of Knowledge (expensive... unless you work in academia or a large corporation and get everything for FREE) . Great! Now you have the reference and probably the abstract, but you would like to check the full publication for some useful information. And there is the PAY button of 36 USD - what to do? Paying is of course a good option. However, if you want to scan quite a few papers this could become easily very expensive... There are other ways! We like to share our experiences of cost and time-efficient approaches. Today, we feature ACCESS, the second of three categories:

Featured tools today in the category ”ACCESS” DeepDyve DeepDyve is the Spotify for scientific literature! You can read as many publications as you like, but you can not download them. The costs are about 1 USD per day, if a full year is "booked". And there is an allowance to print 20 and sometimes even 40 pages per month. Personally, I use DeepDyve since 3 years and are quite happy with it. Many publishers are supporting it, but not all (ACS not 😟). And search does not work with the DOI... but it is just great to view many different publications when researching a topic and not worrying about access rights or costs. ResearchGate Officially, ResearchGate is the largest social networking site for scientists and researchers to ask and answer questions, and find collaborators. Inofficially, it is also a good way to share, respectively access papers. And when using Google Scholar the link to the respective document in ResearchGate is often even displayed on the right side. I believe it is legally a grey area, but it is often quite useful. Sci-Hub Sci-Hub is a pirate site “...to remove all barriers in the way of science”. Well, most likely 100% illegal (Elsevier filed 2015 a legal complaint...), but even Nature nominated the founder, Alexandra Elbakyan, among the top 10 people who mattered most in year 2016. And if you are not afraid of some obscure russian websites and you are desperate to get just this article, it can be an option... Open Access Journals Your lucky day! Open access journals are becoming more and more popular... also because there are options to get access without paying. In 2015 over 10'000 journals were open access journals. However, the publishers work must be paid somehow and in this case the authors, their respective universities and companies or other subsidising organisations pay to publish the articles. Finally You want to use scientific information more? You need to use scientific information more to make better decisions? We might help you - especially in the area of analytical methods, surfaces and interfaces. An informal request and some answer is always free and often gives fresh thoughts in a new directions... ([email protected], +41 79 3129327) Experts, Topics & Impressions - all about Surface Characterisation by IGCThis year we received an extremely positive feedback from the participants. And to summarize it, the success ingredients for this symposium were: Highly qualified participants, very engaged discussions and a nice location beside the Rhine in Cologne. Speakers and participants of BASF, Pfizer, Kronos, Bayer, DSM, Fraunhofer, Clariant, Helmholtz, Schott, Porotec, Adscientis and others exchanged there experiences about How is Inverse Gas and Liquid Chromatography (IGC, ILC), a dynamic adsorption method, used in industry and institutes and what are good – or even bad - ways of use and interpretation? Some content details and insights The conference webpage and the video below provide more insights, but let us summarize a few more details of the different speakers and presentations just here:

A brief workshop in small groups gave all participants the opportunity to reflect many facts and discuss topics as best operating conditions, challenges and new applications. Altogether a memorable event - see you next year!  Does this sound familiar? A major supplier changes the production process – everything is within specifications, but your application just does not work as good as before – or even fails! This was exactly the situation when we analyzed 5 different samples of lactose for a global pharma company in Basel, Switzerland, without knowing anything about the use and the performance of the individual samples of lactose. The 5 powder samples were analyzed by a method called Inverse Gas Chromatography or just IGC, which is able to identify tiny differences in surface properties by dynamic pulse adsorption of 15 or more different gases. One sample clearly stood out in terms of surface accessibility (measured by branched, cyclic and linear alkanes), polarity and acid-base properties (measured by different polar molecules). As it turned out, this was the “good” sample with excellent dissolution behavior – and from the old production. The other samples were clearly differentiated by IGC and their application behaviors were around borderline. IGC data provided not only a clear indication which samples were “good” and “bad”, but also a unique indication, why the samples behaved differently and how the lactose and its surface properties might be optimized. IGC is a powerful technique to characterize surface properties of any powders, particles and fibers. Adscientis SARL and Inolytix Ltd provide an outstanding service lab not only to characterize your samples, but also to provide interpretation and understanding. And soon, together with Porotec, we are just launching a powerful, new IGC instrument to facilitate also your in-house IGC analysis. Do you have comparable problems? The 6th International IGC Symposium, June 20th, 2017, Cologne, brings together experts from BASF, Kronos, Fraunhofer and more. Or just write an email ([email protected]) or take the phone (+41 79 312 9327). Desire for more information?

We started already three years ago with Inolytix. Now we want to extend and improve our services.

At the moment we are supporting R&D departments and product development with very specialised analytical methods to solve their problems. We would like to learn from you what are your challenges in your R&D work and your product development? How can we support you better in your challenges? Please take 2 minutes to answer the following survey. This would help us very much to go into the right direction. |

|

We are eager to support you.

|

RSS Feed

RSS Feed